Digital engineering can be a game changer for designing and building fueling facilities – especially when data is missing, outdated or scattered. Design tools such as LiDAR scanning, point cloud registration, and intelligent 3D models help engineers and designers create accurate construction drawings and reduce changes during the process. That means engineering resources and budget aren’t pushed past their limits.

But what exactly are these tools, and what do they do?

LiDAR stands for Light Detection and Ranging. It’s a cutting-edge surveying method that measures distance to a target by illuminating the object with pulsed laser light and measuring the reflected pulses with a sensor. It can be done on the ground or in the air using a drone. A LiDAR system finds 3D distance information by calculating how long it takes for the light to hit an object before reflecting back to the scanner's receiver. The major applications for LiDAR scanning are in archaeology, city planning and urban engineering, mining and excavation, GPS and navigation, road and bridge construction, and facility design and construction.

Point cloud registration is a product of LiDAR scanning. The intensity of the reflected light determines the scatter and RGB color spectrum of each point in space. Differences in laser return times and wavelengths can be used to make digital 3D representations of the target. This technique produces a full 3D geometrical survey with millimeter accuracy that is called the “point cloud.” Some newer devices collect 4K panorama images which are used to overlay the point cloud and enhance the user viewing experience, as used in the SAIM "Scan" module.

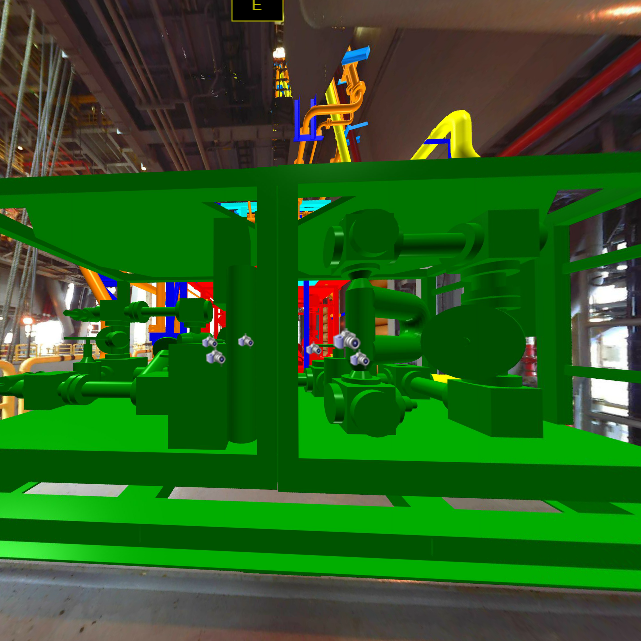

A 3D model is a critical piece in the facility’s management, operation, maintenance, training, engineering and upgrade initiatives. Having an up to date as-built 3D model gives the engineering and maintenance team a head start from the project’s onset by accurately defining coordinates, locations, and dimensions of existing assets. To create the 3D model, point cloud data from the LiDAR scanner and engineering attributes such as pipe class are processed using specialized software to reverse engineer the building blocks for an as-built geometrical, and then intelligent 3D CAD models that have the same high-dimensional accuracy as the source point cloud (0.08" or 2 mm). Various byproducts can be exported from the 3D model, including high-quality professional CAD drawing sets such as ISOs and Bill of Materials (BOM).

Benefits of digital engineering tools like the three described above, include:

- fast survey data collection and reduced operations disruption,

- accurate and continuous survey data collection,

- dimensionally accurate equipment and appurtenance models for each engineering discipline,

- panoramic photographs for virtual site visits,

- dimensionally accurate models for creation of construction drawings and engineering evaluations,

- reduced disruption during construction through prefabrication of critical elements, and

- the ability to utilize models for future projects.

The SAIM platform stems from a 3D representation of the facility, designed from Lidar scans, photogrammetry and 3D as-built models of the brownfield facility. The visual of the facility is useful for offsite owners, consortium members, engineers and operational management. 3D modeling is also incredibly valuable for revamp and development projects at the facility.

Leveraging the latest technology means smarter management of your fuel facilities. Let’s discuss how these tools can support smarter engineering, operation and maintenance to transform your business.

Take the SAIM Facility Assessment and see how digital engineering will improve process and performance at your locations.

Houston-based Smart Asset Integrity Management LLC (SAIM™) benefits from the experience and knowledge of the facility design engineers and specialists at its mother company, Argus Consulting, Inc., a leader in the fuels systems infrastructure engineering industry. For more than 25 years, employee-owned Argus Consulting has focused solely on program management, design, construction administration, and asset integrity management of fuel receiving, storage and distribution facilities and systems.