Learn how SAIM helped to minimize business interruption during an off-spec fuel event at a major airport.

The Situation

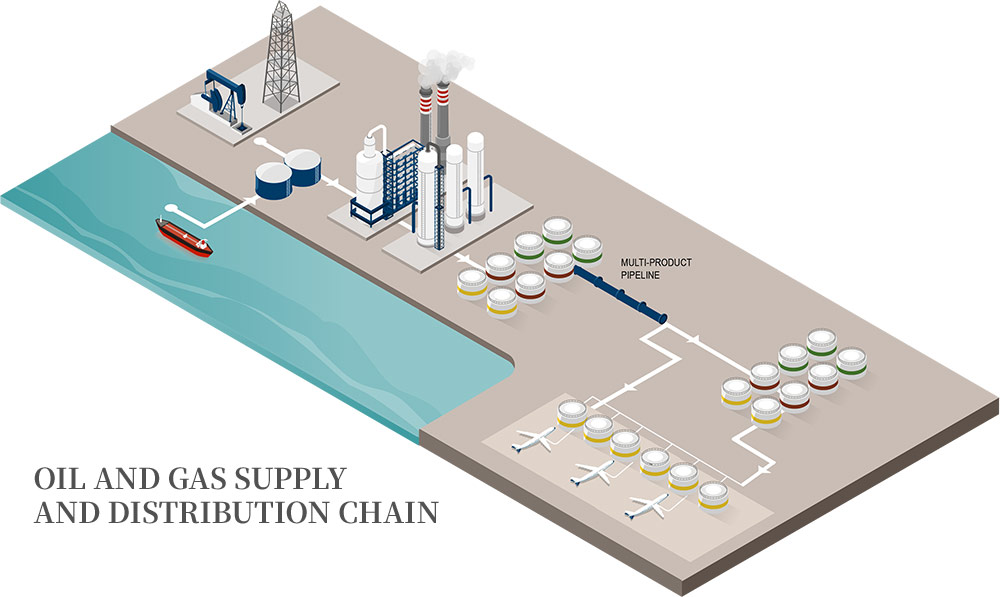

The operator of the fuel storage facility for one of the nation’s busiest airports was notified by the upstream terminal that it received fuel that did not meet Jet Fuel Thermal Oxidation Test (JFTOT) standards. This is one of 16 required criteria to certify fuel to go in an aircraft.

Challenges

SAIM Solutions

The Impact

Using the SAIM platform, the operator and the Engineer of Record could quickly respond and monitor the situation over several days to address the off-spec fuel and avoid costly interruptions to airport operations. Travel to the location was not necessary, saving crucial time and resources.

Everyone involved had immediate and real-time visualization of the current and historical daily uplift, and the quantity of fuel in storage that was available for use. Models were established of fuel availability based upon varying scenario inputs: actual and projected uplift, tank out of service duration, date/time of next scheduled delivery, and volume of scheduled deliveries.

Data supported informed business decision making and gave airline representatives confidence that it was not necessary to reduce airline flight operations at the airport, which is extremely impactful to nationwide air service and customers. It also helped avoid expensive fuel tinkering operations.