The Importance of Knowledge Transfer to the Next Generation

A digital-first strategy is key to closing the knowledge gap

The graying of the workforce in the transportation and critical infrastructure industries is revealing a knowledge gap between generations. Irreplaceable knowledge of the engineering, operations, and maintenance of fueling assets across these industries is leaving at a rapid pace.

Baby Boomer retirement is the biggest “brain drain” America has ever witnessed. The year 2011 began a two-decade period during which no fewer than 10,000 Boomers reach retirement age every single day[1]. In established industries, many retirees are walking out the door with 30+ years’ experience.

Think about it this way:

That’s hard to lose and even harder to replace. In a survey of manufacturing HR professionals, 34% said this would be a real problem, and 11% said it would be a crisis by 2025[2].

The risks of an inefficient workforce.

A poorly trained workforce could be putting themselves and your assets at risk. Ineffective knowledge sharing also endangers team morale and productivity, with the average employee spending over five hours per week seeking or waiting for assistance or information from coworkers, eventually recreating existing work or being delayed in their progress. Additional findings show that 66% of these unshared knowledge delays will last up to one week, and 12% last a month or more[3].

The benefits of a systemic approach to knowledge sharing.

It is not enough to rely on standard training protocols to teach employees how to do their jobs. Today’s managers must put tools in place to encourage and facilitate the transfer of knowledge gained through years of on-the-job experience.

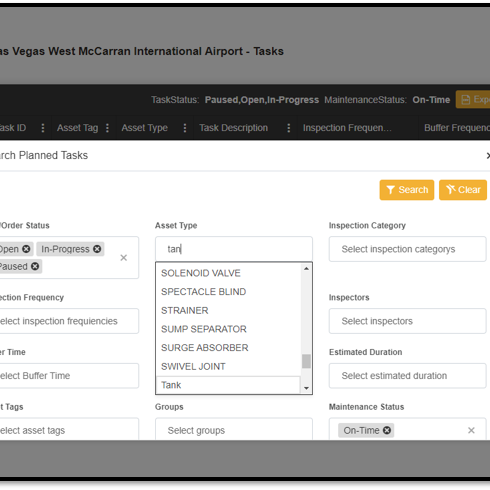

A core principle of the SAIM smart fuels management platform is digitally documenting and communicating critical information. This ensures a smooth knowledge transfer and uninterrupted fuel facility operations.

The SAIM platform enables managers to retain written, video and other training documentation so the next generation of users and operators can gain competencies and experience success in their roles.

- Using reverse engineering through laser scan data, training manuals come to life with virtual simulations within a tank farm 3D model.

- Easy-to-use maintenance and operations digital checklists, alerts, and reminders keep new facility operators and managers on top of scheduled tasks and ongoing reports or inspections.

- Real-time signals help team members track important metrics and provide a centralized source of information to communicate with managers, engineers, and vendors.

Millennials are now the largest generation in the U.S. labor force[4]. They demand digital technologies to do their jobs well and expect workplace learning that uses apps, videos, gamification and virtual reality. They’ve grown up with information at their fingertips and are comfortable sharing what they’ve learned through digital platforms.

Our experienced team members and leaders come from environments where “knowledge is power,” but in today’s workplace the power lies in knowledge sharing. Companies who want to actively capture retiring knowledge and create a modern workforce need to transfer it in a way that will translate into the kind of digital learning and workplace environment the next generation expects.

Ready to transform your knowledge sharing strategies? Schedule a SAIM demo with one of our experts today.

Take the SAIM Facility Assessment to determine the current status of your organization's digital transformation

Want to learn more about digital transformation?

Learn how SAIM is improving the accuracy and efficiency of design and construction with digital engineering tools.

Houston-based Smart Asset Integrity Management LLC (SAIM™) benefits from the experience and knowledge of the facility design engineers and specialists at its mother company, Argus Consulting, Inc., a leader in the fuels systems infrastructure engineering industry. For more than 25 years, employee-owned Argus Consulting has focused solely on program management, design, construction administration, and asset integrity management of fuel receiving, storage and distribution facilities and systems.

Other Interesting Reads:

Well Positioned in 2024

March 19, 2024 2024 Outlook from Tina Lux-Boim, President of SAIM Let me start with a GREAT BIG THANK YOU to each of you and your teams. Last year was tremendous for SAIM. We brought new client locations on board and developed software updates that delivered even more efficiency to the facilities SAIM supports, resulting…

SAIM Team Snapshot: Adeline Ellis

SAIM Team Snapshot: Adeline Ellis December 13, 2023 Get to know Adeline Ellis, Deployment Specialist for SAIM™. Adeline has been with SAIM since the beginning of September, and she is located in Overland Park, Kansas. “I am using my adaptability to make a complex system more user friendly and easier to comprehend.” SAIM Welcomes…

SAIM 2.0 to Launch in Early 2023

February 8, 2023 The new SAIM 2.0 offers improved usability and even more value-driving features. Our engineering and development team is always working to make SAIM even better, and we’re excited to launch SAIM 2.0 in the coming weeks. SAIM 2.0 is a complete rewrite of the system that makes the user interface more intuitive…