Operators streamline how they schedule and conduct maintenance and inspection activities with SAIM's Tank Farm Manager handheld device

The value of SAIM lies in the ability to use real-time data to gain insights, streamline operations and make informed decisions. We’ve taken that a step further by introducing the SAIM Inspect app and handheld device to interface with the Tank Farm module in the field. It supports logging, tracking and intelligence gathering from maintenance and inspection activities at the fuel facility.

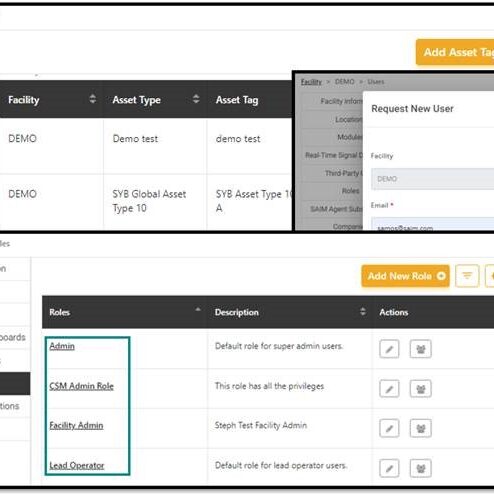

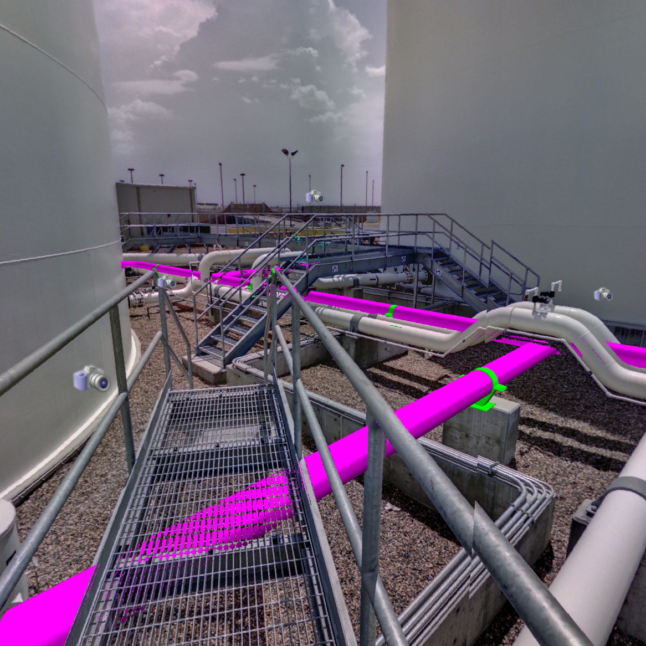

Viewing and recording maintenance & inspection

tasks on the SAIM Inspect app integrated

with the SAIM Tank Farm Manager module.

Benefits for operators:

Using the handheld device, management and engineering support personnel can communicate maintenance and inspection requirements and procedures to local operating staff. With clear expectations and modern tools, operating staff can save time and effort and ultimately go paperless with digital features like adding photos, notes, work order requests and more all while on the go.

Benefits for owners:

Real-time data and cloud-based storage of records provides owners confidence that all required maintenance and inspections are occurring to improve facility performance, maintain compliance and avoid costly unscheduled repairs.

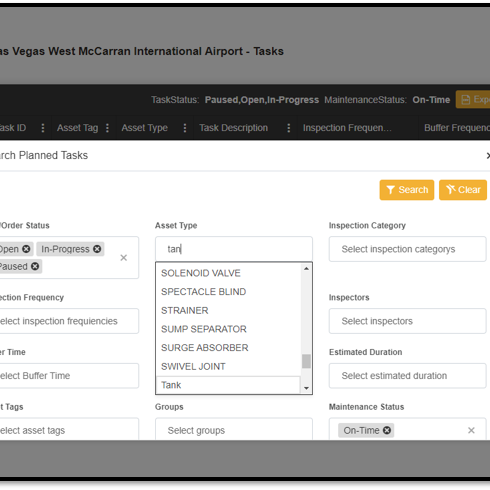

Here's how the SAIM Inspect App and handheld device works:

- Management staff pre-program the intelligent Tank Farm module with required maintenance and inspection tasks and associated frequency.

- The Tank Farm module generates a list of activities for each shift at the facility.

- The operators sync their tasks to their handheld device and go out into the facility to complete their assigned tasks.

- The operator scans the equipment tag associated with the identified task. The operator can then take a photo, file notes, or submit a new work order associated with the task, if needed. The task is marked complete once they’ve concluded all the necessary steps.

- Once the operator has finished their daily tasks, they sync their progress to the SAIM platform. All pictures, attachments, work orders and notes are logged electronically, and the task status is saved.

Here's why it's powerful:

- The app was built using feedback from industry subject matter experts, factoring in weather, visibility, connectivity, and hazardous environments of varied facilities.

- The device’s ability to capture data gives owners even more insights into task completion, facility health and staffing needs.

- Everything is digitized. Paperwork related to all historical and ongoing activities is digitized and stored with the asset on the cloud and is available to support future decision making.

In February, SAIM ran a successful proof of concept in the field, with operators and owners at Oakland International Airport. We recently expanded that field trial to Las Vegas International Airport.

Operators who have been part of the handheld pilot program applaud the app’s workflow and simplicity.

Management likes the increased transparency and says they’ve been “waiting on a device like this for years.”

Operators save time and eliminate pen-to-paper hassle by scanning SAIM tags on facility equipment and logging maintenance tasks and work orders through the SAIM Inspect app on approved, intrinsically safe handheld devices.

This device is a significant leap forward for SAIM and proves the extension of the platform to a mobile device is possible in a field setting, providing even more data and insights for SAIM clients.

Houston-based Smart Asset Integrity Management LLC (SAIM™) benefits from the experience and knowledge of the facility design engineers and specialists at its mother company, Argus Consulting, Inc., a leader in the fuels systems infrastructure engineering industry. For more than 25 years, employee-owned Argus Consulting has focused solely on program management, design, construction administration, and asset integrity management of fuel receiving, storage and distribution facilities and systems.

Other Interesting Reads:

Well Positioned in 2024

March 19, 2024 2024 Outlook from Tina Lux-Boim, President of SAIM Let me start with a GREAT BIG THANK YOU to each of you and your teams. Last year was tremendous for SAIM. We brought new client locations on board and developed software updates that delivered even more efficiency to the facilities SAIM supports, resulting…

SAIM Team Snapshot: Adeline Ellis

SAIM Team Snapshot: Adeline Ellis December 13, 2023 Get to know Adeline Ellis, Deployment Specialist for SAIM™. Adeline has been with SAIM since the beginning of September, and she is located in Overland Park, Kansas. “I am using my adaptability to make a complex system more user friendly and easier to comprehend.” SAIM Welcomes…

SAIM 2.0 to Launch in Early 2023

February 8, 2023 The new SAIM 2.0 offers improved usability and even more value-driving features. Our engineering and development team is always working to make SAIM even better, and we’re excited to launch SAIM 2.0 in the coming weeks. SAIM 2.0 is a complete rewrite of the system that makes the user interface more intuitive…

A Focus on Progress and Vision in 2023

February 8, 2023 Tina Lux-Boim, SAIM’s President, shares a thank you message to clients and her focus areas for 2023 as SAIM continues its growth trajectory. Thank you for your continued trust and support of SAIM. I’m in awe of our progress since I joined SAIM in the spring of 2021. The software and the…

SAIM Team Snapshot: Melissa Wiggin

SAIM Team Snapshot: Melissa Wiggin February 8, 2023 Get to know Melissa Wiggin, Senior Accountant for SAIM™.Melissa has been with SAIM since 2022, and she is located in Boca Raton, Florida. What is the best career lesson you’ve learned so far? To not fear hearing the answer ‘no’ to a question. If someone says…

SAIM Team Snapshot: Shelby Robbe

SAIM Team Snapshot: Shelby Robbe July 15, 2022 Get to know Shelby Robbe, Client Success Manager for SAIM™. Shelby has been with SAIM since 2020, and she is located in Overland Park, Kansas. What five words would you use to describe SAIM, LLC.? Rewarding. Exciting. Challenging. Collaborative. Supportive. What does your role as a…

SAIM Team Snapshot: Shane Busch

SAIM Team Snapshot: Shane Busch June 30, 2022 Get to know Shane Busch, Digital Modeling Manager for SAIM™. Shane has been with SAIM since 2021, part of the Argus fuel system design team since 2015, and is located in Overland Park, Kansas. What is the best career lesson you’ve learned so far? Learn as…

SAIM Team Snapshot: Tina Lux-Boim

SAIM Team Snapshot: Tina Lux-Boim March 21, 2022 Get to know Tina Lux-Boim, President of SAIM™. Tina joined the SAIM team in 2020, and she is located in Overland Park, Kansas. What is the best career lesson you’ve learned so far? Maintaining integrity and ethics is foundational to any sustainable success and more importantly…

Airport Improvement Magazine Showcases SAIM’s Impressive Pilot Results

Check out the May 2021 issue of Airport Improvement Magazine for details on the success of SAIM’s pilot tests at McCarran International Airport in Las Vegas and California’s Oakland International Airport. With our pilot complete, SAIM is ready to expand to airports across the United States and beyond. Uncover the real-world value of SAIM by…

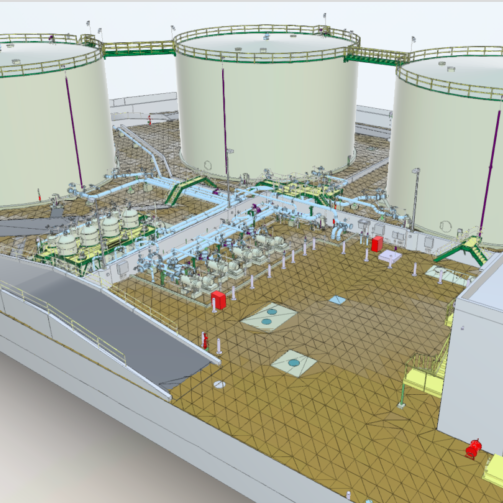

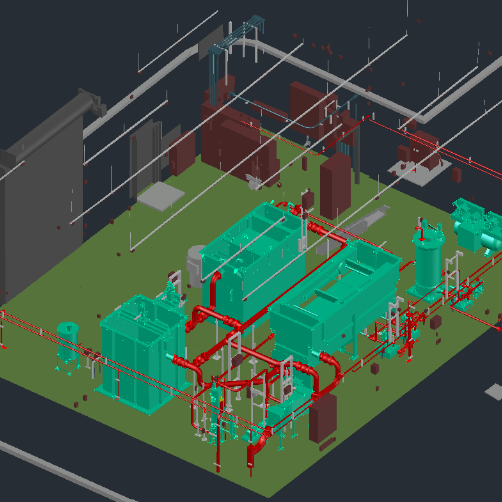

Improve the Accuracy and Efficiency of Design and Construction with Digital Engineering Tools

October 19, 2020 Minimize Errors and Reduce Costs Using Digital Engineering Tools Digital engineering tools, like LiDAR scanning, point cloud registration and 3D modeling, guide design and construction projects from start to finish, minimizing errors and reducing costs. Here’s a real-world example from an industrial wastewater treatment plant that needed to modify piping associated with…

LiDAR Scanning: The Foundation of Digital Transformation

September 16, 2020 Your Facility’s Digital Transformation Begins with LiDAR LiDAR scanning is the foundation for accurately capturing the geometric data and measurements of the assets within a facility. Put simply, LiDAR scanning is the first step in creating an as-built 3D CAD model of your tank farm. Without LiDAR scanning, digital transformation of your…

Digital Engineering: Defined

August 26, 2020 Digital engineering can be a game changer for designing and building fueling facilities – especially when data is missing, outdated or scattered. Design tools such as LiDAR scanning, point cloud registration, and intelligent 3D models help engineers and designers create accurate construction drawings and reduce changes during the process. That means engineering…

Owners, Operators, and Engineers Get on the ‘SAIM’ Page With New Asset Management Platform for Oil & Gas Infrastructure

July 13, 2020 We are excited to bring owners, operators, and engineers a new technology that will revolutionize the fuel storage industry. After a successful two-year pilot program, SAIM™, a digital engineering asset management solution is ready for market. Oil and gas facilities, such as fuel systems and tank farms, will benefit from the smarter…