Your Facility's Digital Transformation Begins with LiDAR

LiDAR scanning is the foundation for accurately capturing the geometric data and measurements of the assets within a facility. Put simply, LiDAR scanning is the first step in creating an as-built 3D CAD model of your tank farm. Without LiDAR scanning, digital transformation of your fuel facility is not complete.

Good news though, the field execution of LiDAR scanning is non-intrusive and won’t affect a facility’s normal operations.

Collecting facility data with the

non-intrusive LiDAR scanning survey.

LiDAR: Introduction to the Process

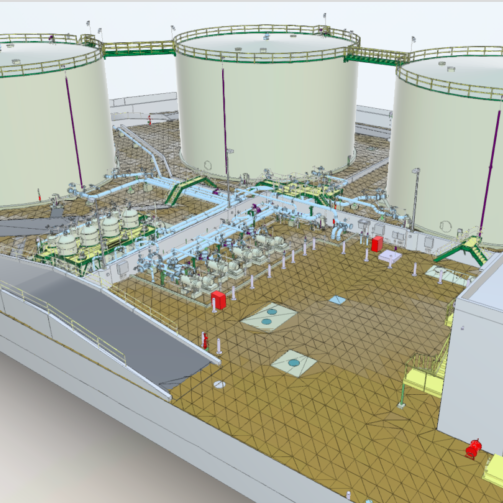

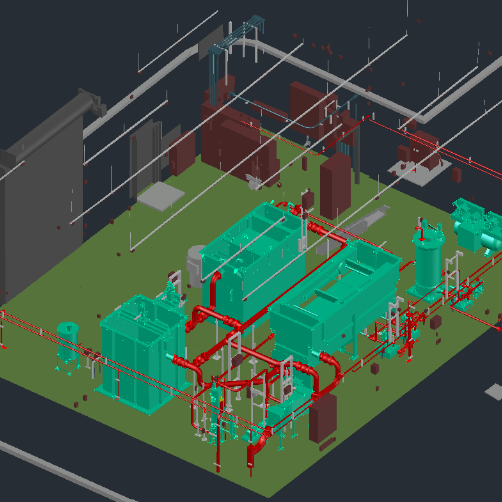

The first step is producing an accurate as-built geometric model by collecting point cloud data of the surfaces using LiDAR terrestrial and/or drone scanners in conjunction with the Total Station survey.

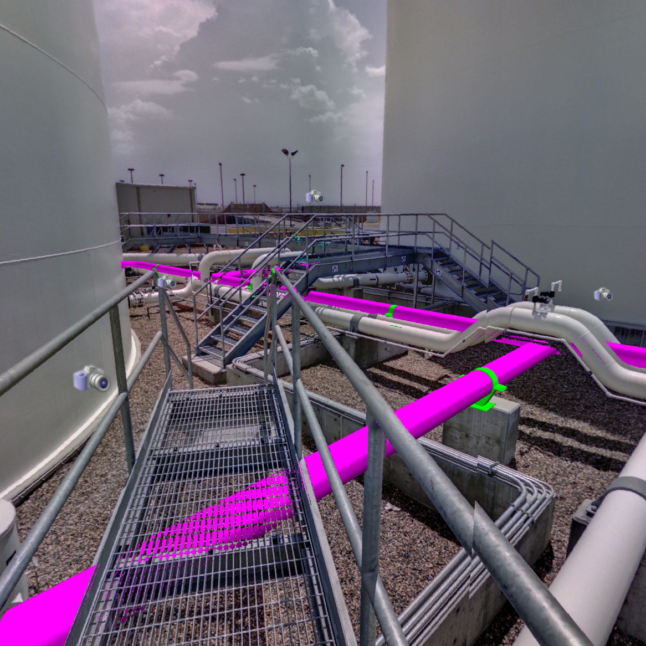

The scanner is placed at multiple locations throughout the facility and/or a drone flies above to collect geometrical point cloud data. A point cloud is a set of data points in space. Point clouds are datasets that measure many points on the external surfaces of objects around them. Simultaneously, 4K realistic high-dynamic-range (HDR) panoramic photos are collected at each scan position to be used for virtual walk throughs. Usually, full coverage point cloud data includes equipment, piping, ground, structures, buildings and miscellaneous components.

Next, the office work starts with a process called registration. Scans are combined into a unified cloud model of the facilities by tying the cloud points to the plant’s coordinate system. The cloud model is then imported into software for reverse engineering of the geometrical 3D model.

Whatever eyes can see, the LiDAR scan collects with ±2mm (0.08 in) dimensional accuracy. However, the LiDAR scanning data points are usually all above-ground geometries including, but not limited to:

- all mechanical equipment (including top of tanks),

- process & utility piping,

- supports and structures,

- civil components including the administration/operations building(s), pads, foundations, dikes, sumps, ramps, handrails,

- major electrical equipment including generators, control panels, junction boxes, and

- major instrumentation including control valves and flow meters.

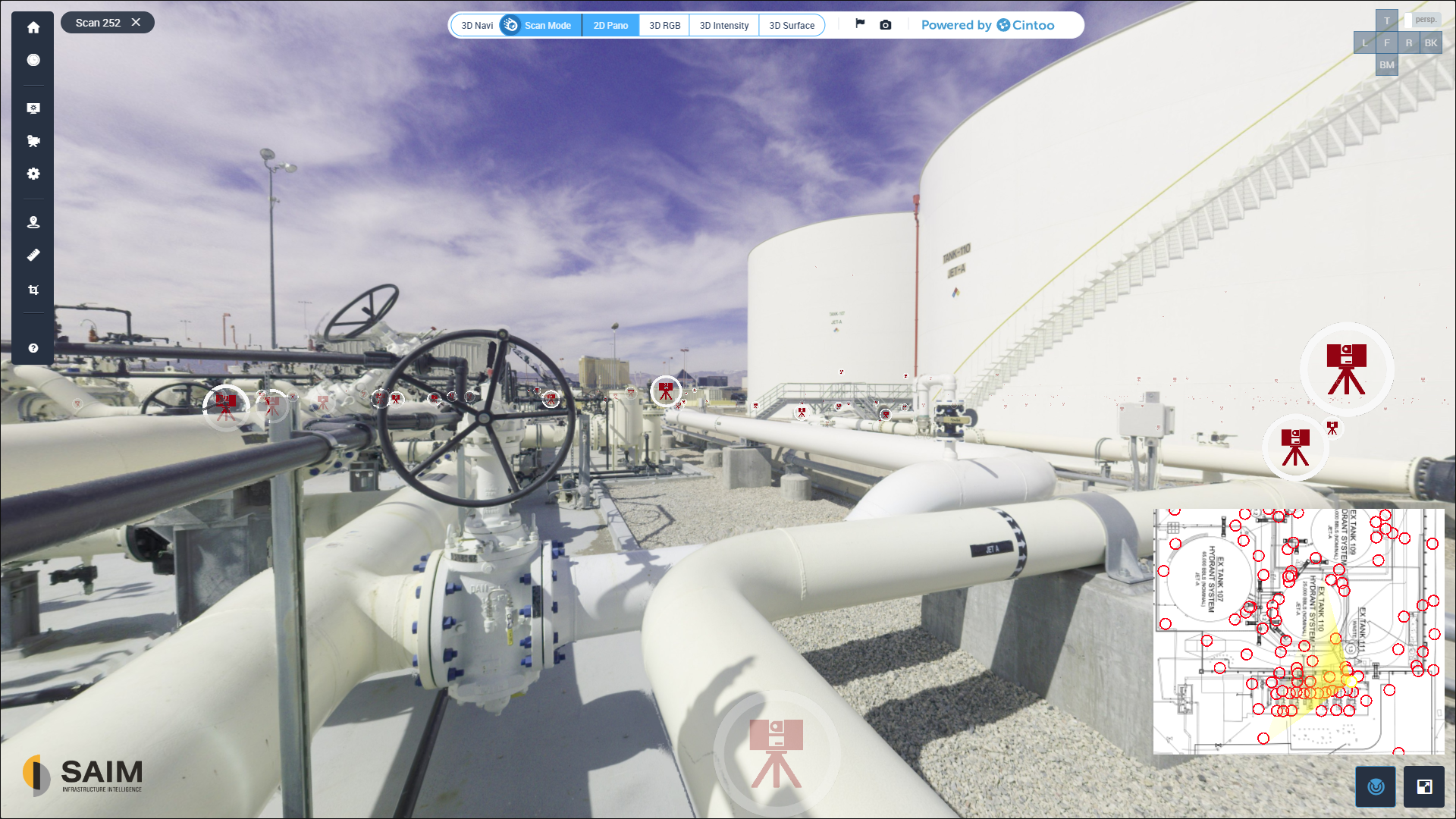

What Does a Facility Look Like After a SAIM LiDAR Scan?

Below is a preview of a fuel facility's scans hosted within the SAIM Platform. The red dots on the right of the screen show the many point cloud data sets that SAIM users can click through to view the facility from all available angles

Additional Benefits of LiDAR: Inspection, Construction and More

There are many benefits of LiDAR scanning in addition to producing accurate drawings of your facility that most likely was built before computers and may not have documentation of changes made due to new regulations, improved processes, and industry innovations. Collecting accurate geometrical data of your facility through LiDAR scanning also supports important inspection services:

- API 653 tank out-of-roundness analysis,

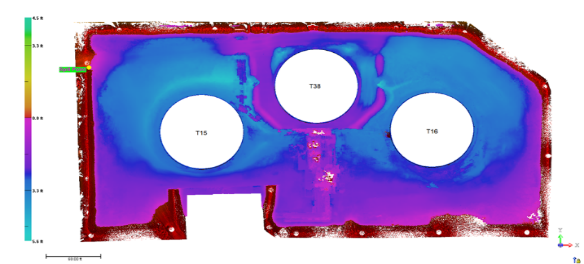

- secondary containment dike volume analysis,

- tank strapping,

- ASME B31.3 pipe bulge/ deformation,

- ASME Sec VIII Div. 1 & 2 pressure vessel integrity & Finite Element Analysis,

- pipe fabrication and pipe fitting support, and

- local deformation analysis.

LiDAR scans are also valuable for construction and fabrication industry support of the unique and large-scale structures that make up your fuel and pipeline systems. The accuracy of your scans greatly increases the efficiency and certainty of your project design and fabrication - reducing the possibility for expensive errors, delays, and operational malfunction when assembling your structural components during construction.

Spill point identified by secondary containment dike volume analysis.

The LiDAR scan process is a quick phase to complete, and gives your facility the first building blocks in place for a successful, powerful, and incredibly valuable digital transformation.

Houston-based Smart Asset Integrity Management LLC (SAIM™) benefits from the experience and knowledge of the facility design engineers and specialists at its mother company, Argus Consulting, Inc., a leader in the fuels systems infrastructure engineering industry. For more than 25 years, employee-owned Argus Consulting has focused solely on program management, design, construction administration, and asset integrity management of fuel receiving, storage and distribution facilities and systems.

Other Interesting Reads:

Well Positioned in 2024

March 19, 2024 2024 Outlook from Tina Lux-Boim, President of SAIM Let me start with a GREAT BIG THANK YOU to each of you and your teams. Last year was tremendous for SAIM. We brought new client locations on board and developed software updates that delivered even more efficiency to the facilities SAIM supports, resulting…

SAIM Team Snapshot: Adeline Ellis

SAIM Team Snapshot: Adeline Ellis December 13, 2023 Get to know Adeline Ellis, Deployment Specialist for SAIM™. Adeline has been with SAIM since the beginning of September, and she is located in Overland Park, Kansas. “I am using my adaptability to make a complex system more user friendly and easier to comprehend.” SAIM Welcomes…

SAIM 2.0 to Launch in Early 2023

February 8, 2023 The new SAIM 2.0 offers improved usability and even more value-driving features. Our engineering and development team is always working to make SAIM even better, and we’re excited to launch SAIM 2.0 in the coming weeks. SAIM 2.0 is a complete rewrite of the system that makes the user interface more intuitive…

A Focus on Progress and Vision in 2023

February 8, 2023 Tina Lux-Boim, SAIM’s President, shares a thank you message to clients and her focus areas for 2023 as SAIM continues its growth trajectory. Thank you for your continued trust and support of SAIM. I’m in awe of our progress since I joined SAIM in the spring of 2021. The software and the…

SAIM Team Snapshot: Melissa Wiggin

SAIM Team Snapshot: Melissa Wiggin February 8, 2023 Get to know Melissa Wiggin, Senior Accountant for SAIM™.Melissa has been with SAIM since 2022, and she is located in Boca Raton, Florida. What is the best career lesson you’ve learned so far? To not fear hearing the answer ‘no’ to a question. If someone says…

SAIM Team Snapshot: Shelby Robbe

SAIM Team Snapshot: Shelby Robbe July 15, 2022 Get to know Shelby Robbe, Client Success Manager for SAIM™. Shelby has been with SAIM since 2020, and she is located in Overland Park, Kansas. What five words would you use to describe SAIM, LLC.? Rewarding. Exciting. Challenging. Collaborative. Supportive. What does your role as a…

SAIM Team Snapshot: Shane Busch

SAIM Team Snapshot: Shane Busch June 30, 2022 Get to know Shane Busch, Digital Modeling Manager for SAIM™. Shane has been with SAIM since 2021, part of the Argus fuel system design team since 2015, and is located in Overland Park, Kansas. What is the best career lesson you’ve learned so far? Learn as…

SAIM Team Snapshot: Tina Lux-Boim

SAIM Team Snapshot: Tina Lux-Boim March 21, 2022 Get to know Tina Lux-Boim, President of SAIM™. Tina joined the SAIM team in 2020, and she is located in Overland Park, Kansas. What is the best career lesson you’ve learned so far? Maintaining integrity and ethics is foundational to any sustainable success and more importantly…

Airport Improvement Magazine Showcases SAIM’s Impressive Pilot Results

Check out the May 2021 issue of Airport Improvement Magazine for details on the success of SAIM’s pilot tests at McCarran International Airport in Las Vegas and California’s Oakland International Airport. With our pilot complete, SAIM is ready to expand to airports across the United States and beyond. Uncover the real-world value of SAIM by…

Improve the Accuracy and Efficiency of Design and Construction with Digital Engineering Tools

October 19, 2020 Minimize Errors and Reduce Costs Using Digital Engineering Tools Digital engineering tools, like LiDAR scanning, point cloud registration and 3D modeling, guide design and construction projects from start to finish, minimizing errors and reducing costs. Here’s a real-world example from an industrial wastewater treatment plant that needed to modify piping associated with…

LiDAR Scanning: The Foundation of Digital Transformation

September 16, 2020 Your Facility’s Digital Transformation Begins with LiDAR LiDAR scanning is the foundation for accurately capturing the geometric data and measurements of the assets within a facility. Put simply, LiDAR scanning is the first step in creating an as-built 3D CAD model of your tank farm. Without LiDAR scanning, digital transformation of your…

Digital Engineering: Defined

August 26, 2020 Digital engineering can be a game changer for designing and building fueling facilities – especially when data is missing, outdated or scattered. Design tools such as LiDAR scanning, point cloud registration, and intelligent 3D models help engineers and designers create accurate construction drawings and reduce changes during the process. That means engineering…

Owners, Operators, and Engineers Get on the ‘SAIM’ Page With New Asset Management Platform for Oil & Gas Infrastructure

July 13, 2020 We are excited to bring owners, operators, and engineers a new technology that will revolutionize the fuel storage industry. After a successful two-year pilot program, SAIM™, a digital engineering asset management solution is ready for market. Oil and gas facilities, such as fuel systems and tank farms, will benefit from the smarter…