Capture What Your Experts Know, and Make It Easy for the Next Person to Learn It.

The Challenge in the Field.

When experienced team members retire or move to new roles, years of site-specific knowledge can disappear overnight. New operators, managers, or business leaders often struggle to learn the facility without shadowing someone who “knows the system.” Training documentation varies, and important details live in notebooks, memory, or personal files. The result is slow onboarding, inconsistent work, and rising operational risk.

The SAIM Solution.

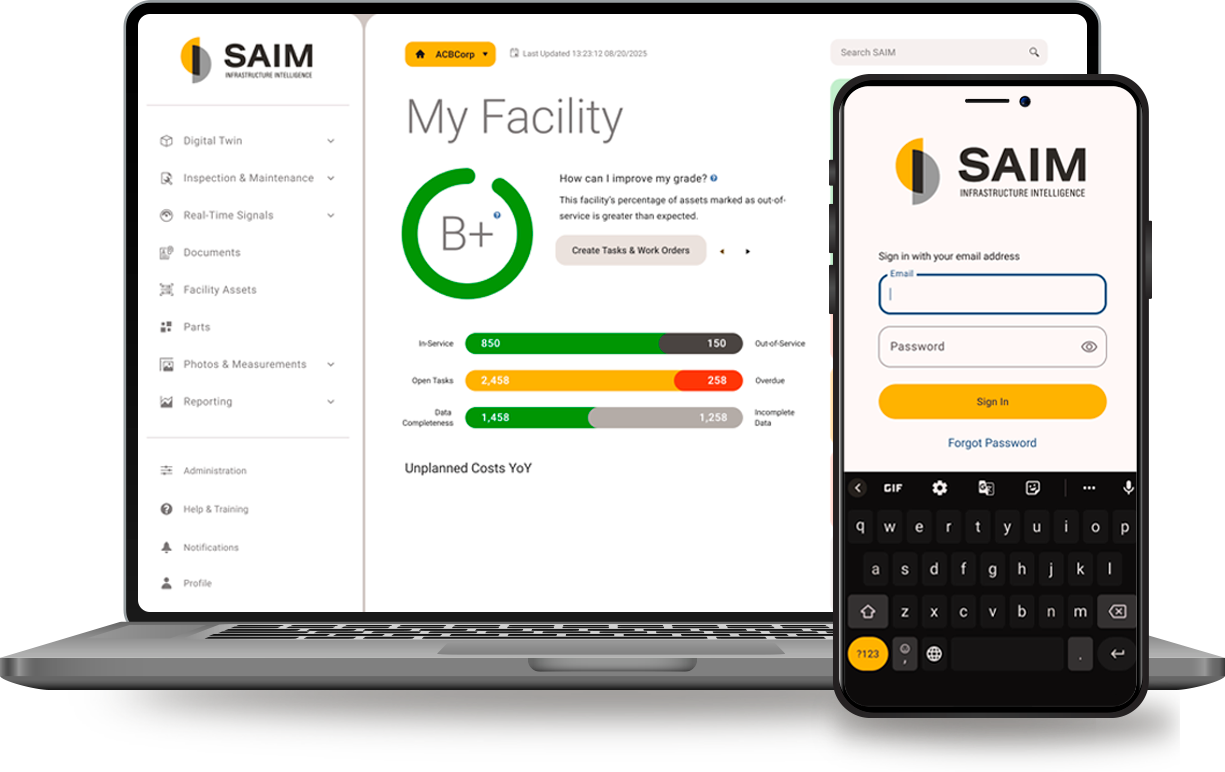

SAIM captures what your experts know and makes it easy for the next person to learn it. SOPs, O&M manuals, videos, photos, notes, and asset histories are stored in one place and linked directly to the equipment they support. Teams can walk the 3D model, follow guided tasks, and review best practices before ever stepping onsite. Training becomes faster, more consistent, and grounded in reliable, searchable facility knowledge.

Centralized Knowledge Management for Maintenance Teams.

SAIM captures, standardizes, and organizes essential procedures, equipment documentation, and process guidelines so knowledge stays in the organization. The Personnel Management module’s Certifications tool tracks inspector qualifications, specialized training, and renewal dates—ensuring only qualified personnel handle critical tasks.

With this single source of truth, your maintenance and operations teams can follow the same playbook, improving consistency, safety, and compliance while reducing downtime.

Role-Based Digital Training for Faster Onboarding.

SAIM’s refreshed maintenance team onboarding and training program makes learning faster and more effective. Through role-based learning paths, interactive storylines, and real-world application scenarios, new hires get up to speed quickly while experienced staff can sharpen advanced skills.

On-demand video training in the SAIM Support Center keeps resources available anytime, anywhere. Essentials Skills courses teach core platform functions, while Advanced Training dives into specialized workflows—ensuring your team can use SAIM to its fullest potential in daily operations.

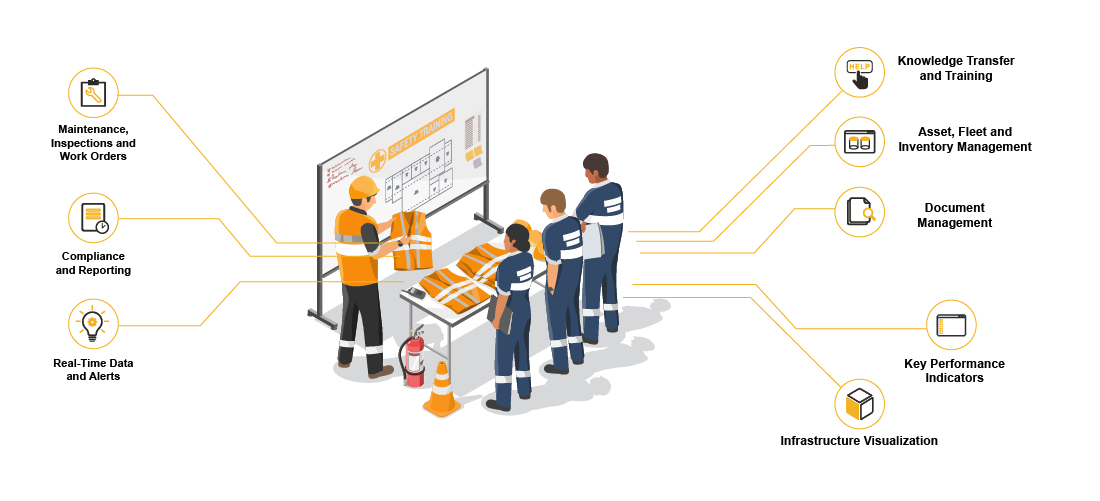

See SAIM Capabilities in Action

Maintenance, Inspections, and Work Orders

Maintenance, Inspections, and Work Orders

Centralize inspections, work orders, and asset care. Track maintenance in real time, streamline field operations, and improve consistency across locations. Learn MoreCompliance and Forms

Compliance and Forms

Digitize compliance with automated forms, recurring tasks, and audit-ready records. Keep O&M documentation organized and accessible from anywhere. Learn MoreReal-Time Data and Alerts

Real-Time Data and Alerts

Monitor equipment health with live signals, trends, and anomaly alerts. Detect issues early, troubleshoot quickly, and keep operations running. Learn MoreInfrastructure Visualization

Infrastructure Visualization

Explore your facility in 3D with SAIM’s Digital Twin. See components in detail, navigate assets remotely, and collaborate faster with up-to-date spatial information. Learn MoreKnowledge Transfer & Training

Knowledge Transfer & Training

Capture critical knowledge and standardize onboarding. Build role-based training that reduces field exposures, improves retention, and strengthens operational consistency. Learn MoreAsset, Fleet & Inventory Management

Asset, Fleet & Inventory Management

Track assets, fleet, and inventory in real time. Manage lifecycle, monitor utilization, and plan maintenance and parts needs to reduce downtime and improve budgeting. Learn MoreDocument Management

Document Management

Centralize facility info in one secure, searchable library. Store drawings, manuals, SOPs, permits, and more with version control and easy access from the field or office. Learn MoreCustom Reporting & Dashboards

Custom Reporting & Dashboards

Roll up inspections, work orders, and monitoring data into organized dashboards. Spot risks, track trends, and make informed decisions faster. Learn MoreSAIM Unlocks Your Team’s Potential.

See how SAIM can maximize your investment and minimize risks for your team, company and operations.- Know it’s getting done. See what’s been inspected, serviced or skipped.

- Avoid costly surprises. Spot possible issues early with live facility data, trends, and predictive insights.

- Stay audit-ready. Keep critical records centralized and accessible when you need them.